A yearly maintenance contract is a proactive service agreement that ensures your critical assets receive scheduled upkeep and priority support for a fixed annual fee. It transforms your approach from reactive, costly emergency repairs to a predictable, strategic partnership for long-term operational health.

So, What Exactly Is a Yearly Maintenance Contract?

Think of a yearly maintenance contract (YMC) as an insurance policy or a wellness plan, but for your most important physical assets. Whether it’s your office’s IT network, the building’s HVAC system, or a crucial piece of factory machinery, a YMC keeps them in top shape. Instead of frantically calling for a technician after a catastrophic failure, you have a dedicated team of experts focused on preventing problems before they start.

It’s a straightforward partnership built on a simple, proven idea: it’s always better—and cheaper—to keep things running smoothly than to fix them after they’ve broken down.

This agreement turns maintenance from a chaotic, unpredictable line item into a stable, budget-friendly operational cost. You pay a set fee, and in return, your provider handles scheduled inspections, preventative tune-ups, and priority emergency support. This isn’t just for massive industrial plants; it’s just as crucial for commercial buildings, residential complexes, and any business relying on its IT infrastructure.

From Reactive Panic to Proactive Partnership

Let’s be honest, operating without a maintenance plan is stressful. You’re constantly in a reactive mode. The server crashes right before a major deadline, the AC gives out during a summer heatwave, or a key machine grinds to a halt, stopping production entirely. This “break-fix” cycle is a recipe for disaster.

Here’s a look at the classic reactive approach versus the smarter, proactive strategy a yearly maintenance contract provides.

Reactive Repairs vs Proactive Yearly Maintenance

| Aspect | Reactive Repairs (No Contract) | Yearly Maintenance Contract (Proactive) |

|---|---|---|

| Cost | High, unpredictable emergency fees and overtime rates. | Fixed, predictable annual or quarterly fee. Easy to budget. |

| Downtime | Significant. Scrambling to find a tech, diagnose, and get parts. | Minimal. Issues are caught early and scheduled repairs prevent major outages. |

| Asset Lifespan | Shortened due to frequent, stressful breakdowns and neglect. | Extended. Regular servicing keeps equipment running efficiently for longer. |

| Business Impact | Major disruptions, lost revenue, and damage to customer trust. | Smooth operations, improved productivity, and enhanced reliability. |

A yearly maintenance contract completely flips the script. It puts a system in place to catch and fix small issues before they ever have a chance to become expensive, business-halting emergencies.

A yearly maintenance contract is more than a service—it’s a strategic decision to invest in operational continuity and asset longevity. It provides peace of mind by guaranteeing that expertise is always on standby, ready to protect your investments and keep your business running without interruption.

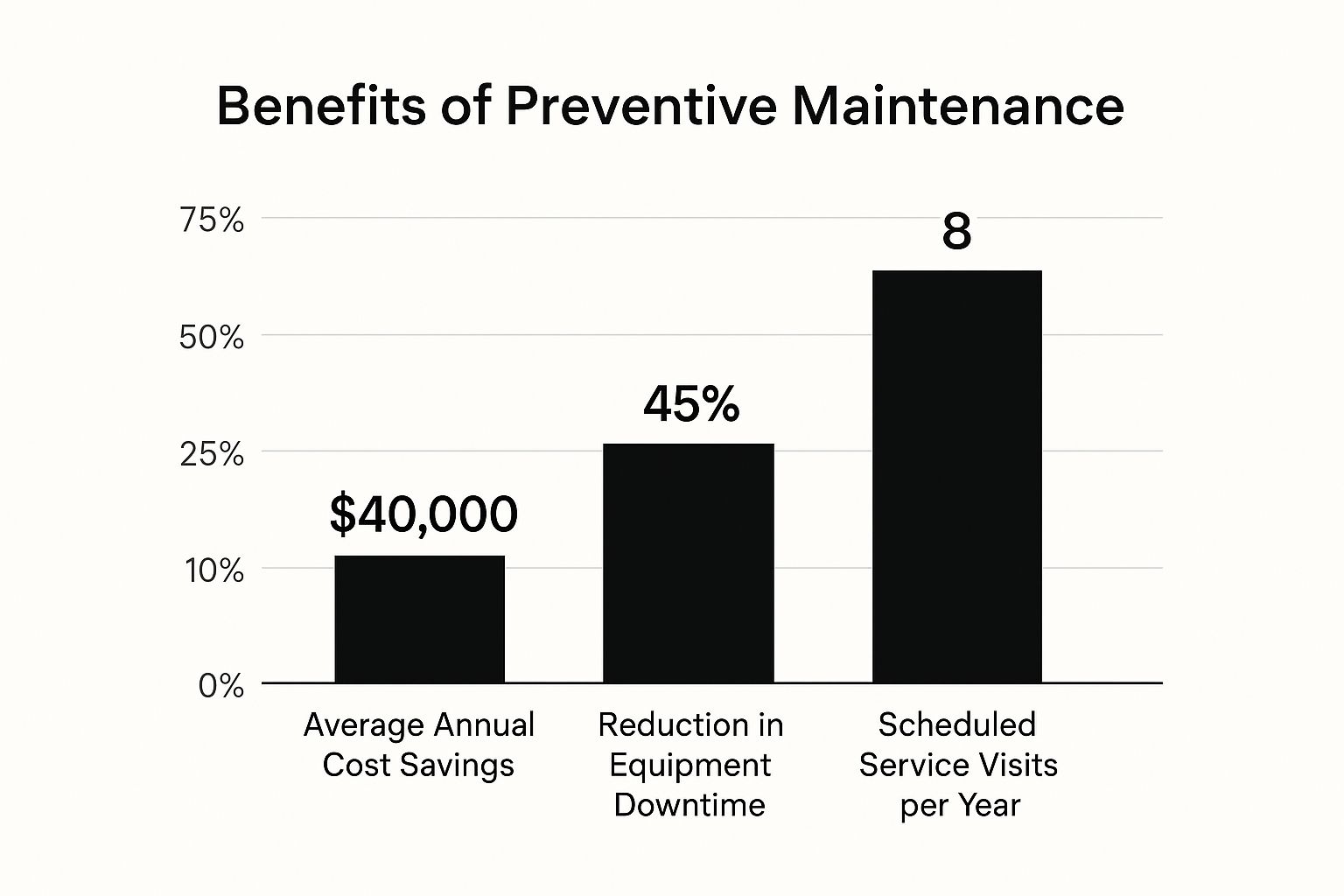

The benefits aren’t just theoretical. The data paints a very clear picture of how this proactive approach pays off.

As you can see, scheduled upkeep directly leads to major cost savings and a huge reduction in disruptive equipment failures. It’s a smart business move, plain and simple.

This strategic shift is gaining momentum worldwide, especially in regions with booming infrastructure. For example, the repair and maintenance market in the Middle East and Africa is expected to grow by over 3.00% annually through 2033, largely because of aging infrastructure and new construction demanding reliable upkeep. As noted by market trend analysis from Data Vibe, yearly maintenance contracts are becoming the standard for their predictable budgeting and ability to maintain quality and safety.

The Strategic ROI of a Yearly Maintenance Contract

It’s easy to think of a yearly maintenance contract (YMC) as just another line item in the budget—a necessary expense. But that’s a limited view. In reality, a well-structured YMC is a powerful strategic investment that pays for itself many times over by protecting your entire business, from your financials to your daily operations.

The most obvious benefit? No more budget-busting surprise repair bills. Without a contract, you’re gambling with unpredictable and often catastrophic costs that always seem to hit at the worst possible moment. A YMC smooths out that financial chaos, converting it into a single, predictable operational expense. This simple shift gives you the power to forecast your finances accurately and invest your capital in growth, not just emergencies.

Maximizing Asset Lifespan and Value

Your equipment and facility infrastructure represent a huge capital outlay. A yearly maintenance contract is, without a doubt, the smartest way to protect that investment. Think of it as a comprehensive wellness program for your most critical assets, ensuring they are always running in peak condition.

This proactive approach prevents the slow, steady wear and tear that ultimately leads to catastrophic failure. It’s the difference between replacing a small, inexpensive bearing during a routine check and dealing with a seized motor that shuts down your entire production line for days.

- Catching Problems Early: Technicians can spot and fix minor issues before they snowball into major, expensive breakdowns.

- Boosting Performance: Properly tuned equipment doesn’t just last longer—it runs more efficiently, uses less energy, and delivers better quality.

- Pushing Back Major Purchases: By extending the life of your current assets, you can delay the significant cost of buying new equipment.

This strategy is especially vital in rapidly expanding markets. For instance, the facility management market in the Middle East and Africa (MEA)—where YMCs are the backbone of operations—was valued around USD 170.77 billion in 2025. With projections showing it could climb to USD 311.67 billion, the demand for structured maintenance is skyrocketing to support all the new infrastructure. You can learn more about these regional dynamics from these market insights from Mordor Intelligence.

Fortifying Safety and Ensuring Compliance

Let’s be direct: a poorly maintained machine is a ticking time bomb. An unexpected failure can create serious hazards for your employees, customers, and anyone on your premises. A formal maintenance plan is one of the most fundamental pillars of a safe work environment.

A robust yearly maintenance contract is not just about asset health; it’s about people’s safety. By formalizing inspections and upkeep, you create a system of accountability that actively reduces workplace risks and ensures you meet regulatory standards.

Having certified professionals conduct regular checks guarantees your equipment meets all local safety codes and industry regulations. This proactive approach helps you sidestep crippling fines, legal troubles, and the brand damage that follows a safety incident. It also gives you a clear paper trail, proving you’re doing your due diligence to keep your facility secure.

Boosting Productivity Through Uninterrupted Operations

At the end of the day, the biggest payoff from a yearly maintenance contract is the dramatic reduction in downtime. Unplanned outages are incredibly costly; some estimates show they cost industrial manufacturers a staggering $50 billion annually. Every single minute a critical system is offline, you’re losing revenue, slipping on deadlines, and frustrating customers.

A YMC is your first line of defense against these crippling disruptions. By scheduling maintenance during quiet periods and catching faults before they cause a shutdown, you create a stable, predictable operational rhythm. This reliability lets your team focus on their actual jobs instead of constantly putting out fires, which directly translates to higher productivity and a healthier bottom line.

What Goes Into a Strong Maintenance Contract?

When a proposal for a yearly maintenance contract lands on your desk, it can feel a bit like trying to read a dense legal document. But getting a grip on its key parts is the only way to know if you’re truly getting the protection you need. A good contract is more than just a list of services; it’s a clear roadmap that shows how your equipment will be cared for, what happens when things go wrong, and exactly what your money is buying.

Think of it like building a house. You need a solid foundation (preventive care), a reliable emergency plan (corrective support), and a clear agreement on who pays for the materials (parts and supplies). Let’s break down these essential pieces so you can look at any proposal with an expert eye.

The Foundation: Preventive Maintenance

This is the proactive heart of any good yearly maintenance contract. It’s all about the schedule of planned visits and routine tasks designed to keep your systems running smoothly and, more importantly, to catch problems before they cause a full-blown failure. A vague promise of “regular check-ups” simply won’t cut it.

A solid contract should get specific:

- Frequency of Visits: How many times a year will a technician show up? This isn’t a random number; it should be based on the equipment’s type, age, and how heavily you use it.

- Specific Tasks: What will they actually do? Look for a detailed checklist that includes things like inspections, cleaning, lubrication, calibration, and any necessary software updates.

- Detailed Reporting: After every visit, you should get a service report. This document should spell out the work performed, the condition of the equipment, and any recommendations for the future.

This is where the real value is. Proactive care is what directly lowers the chances of a disruptive—and expensive—breakdown.

When Things Go Wrong: Corrective and Emergency Support

Even with the best preventive care, equipment can still fail. This is where the contract’s clauses on corrective and emergency support kick in. This section outlines exactly how your provider will respond when something breaks down.

A great yearly maintenance contract doesn’t just promise to fix problems—it guarantees a specific level of responsiveness. This guarantee, often called a Service Level Agreement (SLA), is your assurance that help will arrive when you need it most.

Your contract must clearly state the guaranteed response time. This is the non-negotiable window—the maximum time you’ll have to wait for a technician to arrive after you report an issue. This could be a few hours for mission-critical systems or the next business day for less urgent problems. Without a defined SLA, you’re just hoping for a quick response instead of having a contractual right to one.

The demand for these agreements is growing. The yearly maintenance contract market in the MEA region is expanding, with a projected CAGR of around 6.2% from 2025 to 2030. This growth is heavily driven by the need for reliable HVAC and MEP services in extreme climates. In fact, in 2024, the upgrade and replacement segment made up about 61.64% of HVAC maintenance revenues, showing that modern contracts are increasingly covering both preventive care and equipment updates. You can see more on these trends in the Grand View Research findings on HVAC maintenance services.

Covering the Costs: Parts and Consumables

One of the biggest differentiators in any yearly maintenance contract is how it handles the cost of spare parts, labor, and supplies. This usually falls into one of two categories.

| Contract Type | What It Covers | Best For |

|---|---|---|

| Comprehensive Contract | Includes the cost of labor and all spare parts needed for repairs. | Businesses that want a fixed, all-inclusive budget with zero surprise invoices for parts. |

| Non-Comprehensive Contract | Covers only the cost of labor for service visits. You pay for any required spare parts separately. | Organizations that prefer a lower initial contract price and are comfortable budgeting for replacement parts as the need arises. |

The right choice here really comes down to your budget strategy and how much risk you’re willing to take. A comprehensive contract gives you total cost predictability. A non-comprehensive one has a lower upfront fee but introduces the variable cost of parts. Whichever you choose, make sure the contract spells it out clearly to avoid headaches and disputes down the road.

Decoding the Cost of Your Maintenance Contract

Trying to pin down a single, fixed price for a yearly maintenance contract is a bit like asking, “How much does a car cost?” The answer is always, “It depends.” There’s no universal price tag because the final cost is a direct reflection of the specific equipment you need covered, the level of service you expect, and the amount of risk you’re asking the provider to take on.

Getting a handle on these cost drivers is key. It helps you look past the sticker price and see the actual value in a proposal. After all, a cheap contract that doesn’t cover your most essential equipment will end up costing you a fortune in the long run when something inevitably breaks.

The Nature of Your Assets

The biggest factor influencing the price is the equipment itself—what it is, how old it is, and how complicated it is. Think of it like insurance. Covering a high-performance sports car is always going to be more expensive than insuring a reliable family sedan. The same logic applies to your business assets.

- Asset Type and Complexity: A standard office printer is one thing. A complex IP telephony system or a server room full of high-density racks? That’s a whole different ballgame, requiring technicians with very specific, often certified, skills. That expertise costs more.

- Age and Condition: Let’s be honest, older equipment is just more likely to fail. A maintenance contract for assets that are getting on in years will naturally have a higher price tag to account for that increased risk and the very real possibility that replacement parts will be harder to find.

- Criticality: How bad is it if this piece of equipment goes down? The contract for a data center’s cooling system—where every minute of downtime can cost thousands—will be far more robust (and expensive) than one for the lights in the breakroom. The price reflects the provider’s responsibility to prevent a catastrophic failure.

Scope of Work and Service Levels

Next up is what you’re actually asking the provider to do. This is defined by the scope of work in your contract. The more you include and the faster you need them to show up, the more it will cost.

A clearly defined scope is your best friend. It eliminates any confusion or finger-pointing when an emergency strikes.

At its core, the cost of your yearly maintenance contract is tied directly to the amount of business risk you are handing over to your service provider. A higher price buys you faster, more thorough protection and, ultimately, greater peace of mind.

This is where your Service Level Agreement (SLA) comes into play. The SLA is the legally binding part of the contract that spells out exactly what the provider promises to deliver.

Here are the service details that really move the needle on price:

- Number of Scheduled Visits: The more preventive maintenance visits you schedule, the more you’ll pay in labor costs. But on the flip side, those regular check-ups dramatically lower your odds of a surprise breakdown.

- Guaranteed Response Time: Need a technician on-site within 2 hours for critical failures? That kind of priority service will cost more than a standard next-business-day response. You’re essentially paying for a spot at the front of the line.

- Comprehensive vs. Non-Comprehensive: A “bumper-to-bumper” comprehensive contract covers all parts and labor, giving you a predictable, fixed cost for the year. A non-comprehensive plan has a lower upfront price, but you’ll be on the hook for the cost of any replacement parts, which can be unpredictable.

When you get a quote, you have to weigh these costs against the potential price of downtime and replacing equipment sooner than you planned. A well-structured yearly maintenance contract isn’t just another expense—it’s a smart investment in keeping your business running smoothly.

How to Choose the Right Service Provider

The value of your yearly maintenance contract is only as good as the provider you sign it with. It’s easy to get bogged down in comparing prices, but choosing the right partner is about much more than that. You’re entrusting a critical part of your business to a team that needs to be skilled, dependable, and honest. A great provider feels like an extension of your own team—proactively looking after your assets and swooping in quickly when something goes wrong.

On the other hand, picking the wrong provider can create more problems than it solves. Think missed appointments, sloppy work, surprise fees, and costly downtime. To avoid that headache, you need a solid game plan for vetting potential partners. This means looking past the sales pitch and really digging into their qualifications, reputation, and how they operate. It’s the only way to find a provider that truly gets your business.

Technical Expertise and Industry Specialization

Not all maintenance providers are created equal. Your first and most important checkpoint is to confirm they have the right technical skills for your specific equipment. A team that’s brilliant with commercial HVAC systems might be completely out of its depth when faced with a sophisticated IP telephony system or high-end server hardware.

You need to ask pointed questions:

- Relevant Experience: Have they actually worked with businesses in your industry? Maintaining equipment in a busy retail store is a world away from managing the IT infrastructure for a school.

- Team Qualifications: What certifications do their technicians hold? Look for official credentials from brands that matter to you, like Cisco, Microsoft, or the manufacturers of your specific equipment. These aren’t just pieces of paper; they’re proof of a commitment to professional standards.

- Training and Development: How do they keep their team sharp? Technology evolves fast, and a provider worth their salt invests in ongoing training to stay on top of the latest trends and techniques.

Doing this homework protects you from signing on with a team that can’t handle the unique challenges your equipment will throw at them. A provider with proven experience in your sector, like OMX Solutions and our focus on UAE businesses, will already understand the local operating environment and compliance landscape.

Reputation and Client Trust

A provider’s track record is where the truth comes out. It tells you everything you need to know about their reliability and service quality. Before you even think about signing a yearly maintenance contract, it’s crucial to do some digging into their reputation. A company can promise the world, but their history with other clients tells the real story.

When vetting a provider, remember that you are not just buying a service; you are entering a long-term partnership. Their reputation for reliability and customer support is just as important as their technical skill.

So, how do you get the real scoop on their reputation? Go beyond the glowing testimonials on their homepage.

- Ask for Case Studies: Request detailed case studies or client references, specifically from businesses that are similar to yours in size and industry. This gives you a practical look at how they solve real-world problems.

- Check Online Reviews: Look for independent reviews on Google or in industry forums. Pay attention to both the good and the bad, and look for any recurring themes in the comments.

- Inquire About Client Retention: A simple but powerful question: what’s their average client relationship length? A high retention rate is a fantastic sign of happy, satisfied customers.

This research helps you build a mental picture of what it’s really like to work with them day in and day out.

Operational Capacity and Resources

A provider might have the most brilliant technicians on paper, but if they’re stretched thin and short on resources, you won’t get the timely service you’re paying for. You need to get a feel for their operational capacity to make sure they can actually deliver on the promises made in their Service Level Agreement (SLA).

Here are the key questions you should be asking:

- Team Size and Structure: How many technicians do they have? How is the team organized? You need to know they have enough people to cover all their clients without you ending up at the back of the line.

- Spare Parts Inventory: Do they keep a local stock of common spare parts for your kind of equipment? Waiting for a critical part to be shipped can turn a minor hiccup into days of downtime.

- Tools and Technology: What diagnostic tools and service management software do they use? Modern tools help technicians pinpoint and fix problems faster, and they can provide you with much more transparent reporting.

Choosing a well-resourced partner gives you peace of mind. When an emergency strikes, you know they have the people, parts, and tools ready to go. This operational strength is the true backbone of a reliable yearly maintenance contract.

Got Questions? We’ve Got Answers

Even after breaking down what goes into a yearly maintenance contract, it’s natural to have a few more questions pop up. Let’s tackle some of the most common ones we hear so you can make your decision with total confidence.

YMC vs. AMC: What’s the Real Difference?

You’ll see two acronyms floating around: YMC (Yearly Maintenance Contract) and AMC (Annual Maintenance Contract). The simple answer? They mean the exact same thing. Both refer to a service agreement that covers your maintenance needs for a 12-month period.

Honestly, don’t get caught up in the acronyms. The name on the top of the page doesn’t matter nearly as much as the details inside. Focus your attention on what the contract actually promises—the scope of work, service levels, and specific inclusions are where the real value lies.

Is This Contract Actually Legally Binding?

Yes, it absolutely is. A yearly maintenance contract is a formal legal document. Its entire purpose is to lay out a clear set of responsibilities for both you and the service provider, protecting everyone involved. That legal weight is precisely why you should never just skim it before signing.

Think of the contract as your primary tool for accountability. It locks in the provider’s commitment to response times and service quality, just as it confirms your payment obligations. It’s designed to prevent confusion and protect both parties’ interests.

Because it’s a binding agreement, you need to treat it like one. Comb through every clause, paying special attention to the payment schedule, what’s covered (and what isn’t), emergency support guarantees, and the rules for ending the contract.

Can I Get a Custom Maintenance Contract?

You should insist on it. A one-size-fits-all plan just doesn’t work for something as important as your business’s core equipment and systems. Every business is different, and a good service provider won’t just allow for customization—they’ll expect it.

You should feel confident negotiating the terms to build a plan that truly fits your operations. This often includes:

- Listing the exact pieces of equipment or systems you want covered.

- Deciding on the frequency of scheduled maintenance visits per year.

- Defining emergency response times that make sense for your business hours.

The right provider acts more like a partner, working with you to draft a yearly maintenance contract that gives you the exact support you need to keep things running smoothly.

At OMX Solutions L.L.C., we specialize in creating customized IT maintenance contracts that align perfectly with your business goals in Dubai and Abu Dhabi. Protect your critical systems and ensure operational continuity by partnering with a team that understands your needs. Secure your free consultation with our IT experts today.